The world of industrial refrigeration is a cornerstone in numerous sectors, providing the essential cooling solutions needed to maintain product integrity and operational continuity. Industrial coil systems are at the heart of this cooling process, offering advanced designs that can handle extensive thermal loads with remarkable efficiency. With innovations continually shaping the landscape, understanding the inherent benefits of these systems is critical for organizations looking to optimize their operations.

Understanding Industrial Coil Systems in Modern Refrigeration

At the core of any refrigeration system lies its ability to transfer heat effectively, and that’s where industrial coil systems play a crucial role. These coils, made from metals like copper or aluminum, circulate refrigerant that absorbs heat from the environment or products, thus lowering the temperature as needed. The design and construction of these coils directly influence the efficiency of the heat exchange process, making them an essential component in the cooling chain.

The use of high-quality materials ensures the longevity and durability of these coil systems, which is vital in industrial settings where downtime can be costly. As a premium form of this necessary component, Industrial coil systems offer robust features suitable for heavy-duty applications and can be customized to meet specific operational demands. By integrating such advanced coils, businesses can significantly enhance the functionality and reliability of their refrigeration units.

Maintenance also plays a part in the effectiveness of these systems. Properly designed coils are easier to clean and repair, which reduces labor costs and minimizes the risk of extended downtimes. Efficient airflow design and anti-corrosion treatments are further benefits that help sustain the coils’ performance over time, proving indispensable in harsh industrial environments.

Enhancing Energy Efficiency With Advanced Coil Design

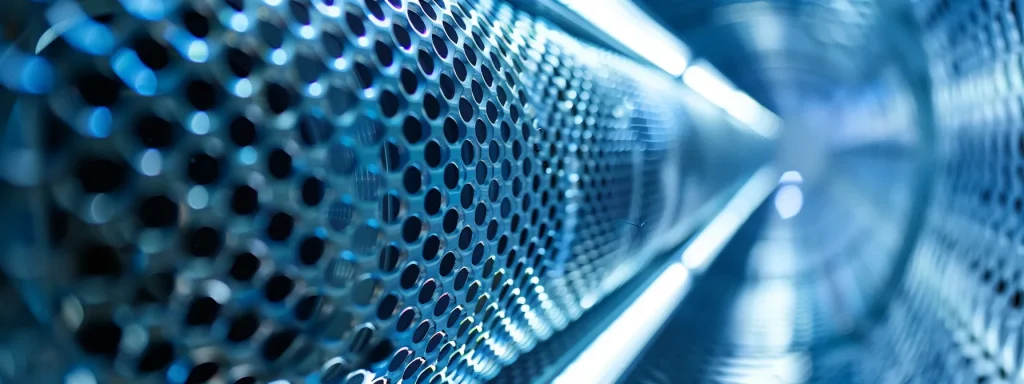

Energy efficiency is crucial in any industry, but particularly in refrigeration, where systems operate continuously and consume considerable amounts of electricity. Advanced coil designs focus on optimizing the surface area and enhancing the heat exchange rate, which allows systems to reach desired temperatures more quickly and with less energy. As a result, businesses can reduce their energy consumption, leading to significant cost savings.

Innovations in fin technology, for instance, play a crucial role in increasing the thermal efficiency of coil systems. By improving the layout and structure of fins, manufacturers ensure that the air moves more smoothly over the coil, enhancing the unit’s overall heat absorption capabilities. This innovation leads to improved energy performance without compromising on cooling power.

Incorporating enhanced coil systems can also impact achieving sustainability goals through HVAC equipment. As many companies strive to reduce their carbon footprint, implementing energy-efficient technologies such as sophisticated coil design grants them a significant advantage in environmental stewardship and compliance with regulatory standards.

The Role of Industrial Coils in Reducing Operational Costs

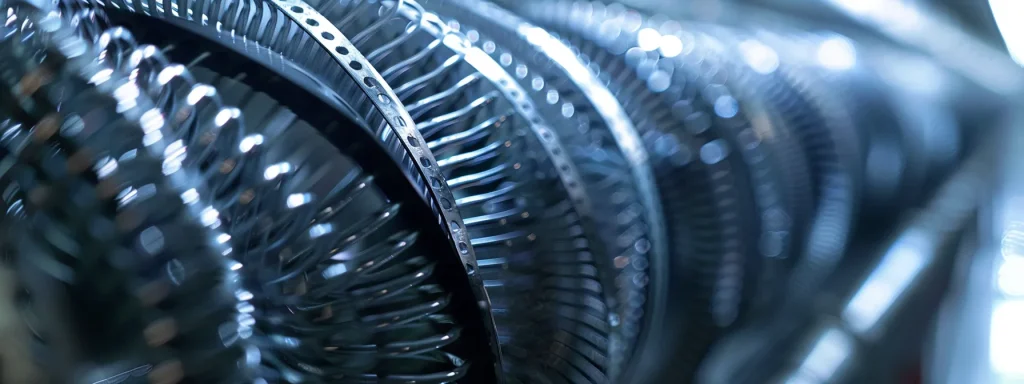

Operational costs in refrigeration go beyond just energy bills; they encompass maintenance, repairs, and system longevity. Industrial coils that are designed to be robust and efficient help in lowering these expenses through reliable performance and less frequent need for intervention. Less time spent on maintenance translates to more productive use of resources and personnel.

A system with high-quality coils also experiences fewer breakdowns, reducing the likelihood of emergency repairs that can incur high costs. With a properly designed coil system, the wear and tear on other components is minimized, which contributes to the overall durability of the refrigeration system. As a result, businesses can enjoy longer intervals between replacements and overhaul work, saving money in the long term.

Furthermore, as environmental regulations become more stringent, companies may face fines and remediation costs if their operations are not up to code. Energy-efficient and environmentally friendly coil systems can help avoid such financial penalties, ensuring that businesses stay within regulatory compliance while also benefiting from lower operational costs.

The Impact of Coil Systems on Refrigeration Performance and Reliability

The performance of industrial refrigeration systems is intrinsically linked to the quality of their coils. Effective heat exchange is the cornerstone of cooling performance, and coils that are specifically tailored for an application can significantly boost a system’s capacity. This is particularly valuable in critical applications where temperature deviations cannot be tolerated, such as in the medical or food industries.

In refrigeration, consistency also matters. Industrial coils contribute to maintaining uniform temperatures, which is essential for many processes. Variations in temperature can lead to inefficiencies and product damage, but well-designed coil systems help mitigate these risks, providing peace of mind for businesses that their operations will run smoothly.

The pivotal role of industrial coils in refrigeration systems is undeniable. Their influence on energy efficiency, operational costs, and system performance highlights their importance in industrial settings. As technology advances, we can expect these systems to become even more integral to maintaining the high standards required in refrigeration.

Read Also: SEO PowerSuite: A Review of the Toolkit for SEO Professionals