When discussing workplace safety, small details often make the biggest difference. One such detail is the toeboard. You might have heard the phrase:

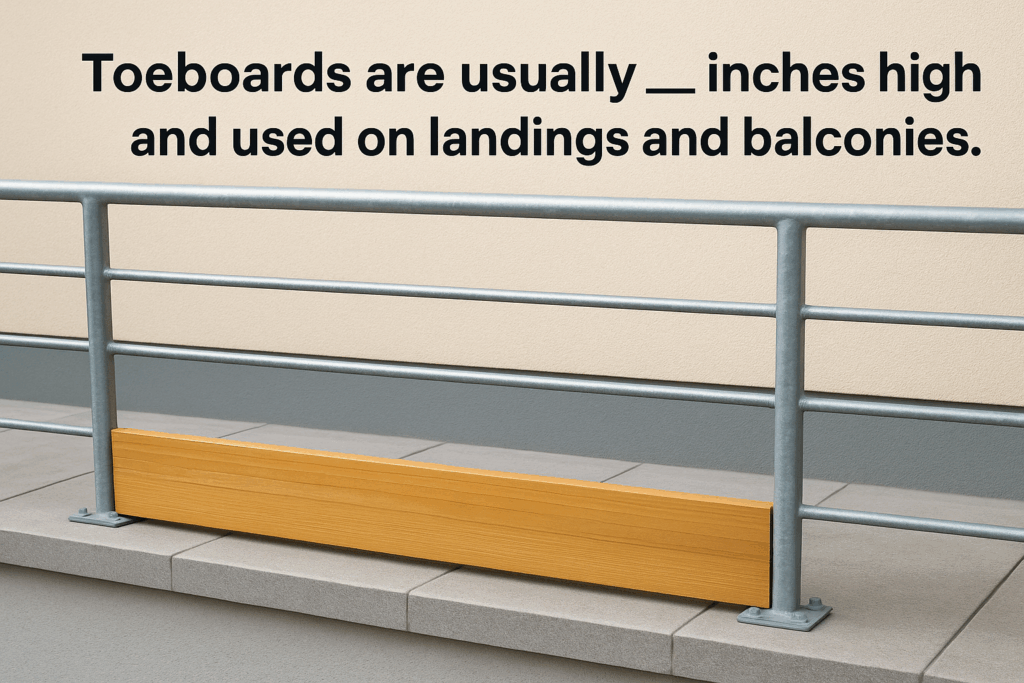

“Toeboards are usually ___ inches high and used on landings and balconies.”

That blank isn’t trivial. The correct answer is that toeboards are usually 3½ inches (8.9 cm) high at minimum, with many organizations choosing a nominal 4 inches for simplicity and compliance with common standards.

This article will provide an in-depth, fact-checked exploration of what toeboards are, why they matter, and the exact requirements that apply to their use. We will draw on OSHA standards, workplace safety guidelines, and engineering best practices. Where rules differ, I will clearly point that out.

By the end, you’ll understand not just the numbers, but the reasoning behind them—and how to apply them on real-world landings, balconies, and platforms.

What Exactly Is a Toeboard?

A toeboard is a short barrier—usually a vertical board, plate, or strip—installed at the edge of elevated surfaces.

-

Purpose: Prevents materials, tools, or small objects from falling off and injuring people below.

-

Typical Locations: Balconies, landings, scaffolds, mezzanines, catwalks, and elevated walkways.

-

Design: Typically made of steel, aluminum, wood, or composite materials. The bottom edge is flush with the surface, and the top edge sits at least 3½ inches high.

The term “toeboard” comes from its position: just above the toes of someone standing near the edge. While modest in size, it plays a critical role in falling-object protection.

OSHA Standards: The Fact-Checked Numbers

The Occupational Safety and Health Administration (OSHA) provides explicit requirements.

1. General Industry (29 CFR 1910.29(k))

-

Height: Minimum 3½ inches (8.9 cm) from the walking surface.

-

Clearance: No more than ¼ inch (0.6 cm) between the toeboard bottom and floor.

-

Strength: Must resist 50 pounds (222 N) of force applied in any direction.

2. Construction Industry (29 CFR 1926.502(j) and 1926.451(h))

-

Minimum height: 3½ inches.

-

Clearance: ¼ inch maximum gap below.

-

Strength: Again, 50 pounds resistance required.

3. Maritime (29 CFR 1917.112)

-

Same baseline requirements: 3½ inches, ≤¼ inch clearance, 50-lb force resistance.

4. State/Local Rules

Some states, like Washington State (WAC 296-307-25030), adopt OSHA’s baseline but allow certain alternatives in niche contexts (for example, vehicle pits at 2½ inches).

✅ Fact-checked conclusion: In most cases, toeboards must be at least 3½ inches high, though 4 inches is often the chosen nominal size in construction and industry.

Why Height Matters

The height of a toeboard is not arbitrary—it directly impacts safety.

Falling Object Hazards

-

Even a small wrench falling from a 10-foot platform can cause injury.

-

A 3½–4 inch barrier effectively blocks most handheld tools and small debris.

Human Factors

-

Toeboards act as a visual edge cue, especially for workers carrying loads.

-

Prevents rolling or sliding materials (bolts, nuts, debris) from escaping.

Compliance & Liability

-

OSHA penalties for missing or inadequate toeboards can exceed $16,000 per violation.

-

If an accident occurs and a missing toeboard is found, liability is significant.

Real-World Applications: Landings and Balconies

Landings

A landing is a flat resting point between stairs or at the top of a stairway. Landings often connect to open edges. A toeboard here:

-

Stops objects dropped on the landing from falling down the stairwell.

-

Works with guardrails and handrails to provide full edge protection.

Balconies

Balconies, whether industrial catwalks or architectural features, are prime locations for toeboards:

-

Prevents tools and debris from falling onto walkways or workers below.

-

Often required in workplaces where multiple floors are occupied.

✅ Fact: In OSHA’s framework, if workers are below an elevated surface and there’s risk of falling objects, a toeboard (or equivalent protection) is required.

Materials and Design Considerations

Common Materials

-

Steel/Aluminum: Strong, durable, long-lasting.

-

Wood: Affordable, easy to install, often temporary.

-

Plastic/Composite: Corrosion-resistant, used in chemical or food industries.

Design Notes

-

Height: 3½–4 inches.

-

Smooth surface to prevent catching clothing.

-

Flush against floor—≤¼ inch gap.

-

Reinforced for impact resistance.

How to Install a Toeboard (Step-by-Step)

Step 1: Assess the Edge

-

Identify all elevated edges where people could be below.

Step 2: Measure

-

Mark 3½ to 4 inches above floor level.

Step 3: Select Material

-

Match environment: Steel for outdoors, composite for corrosive areas, wood for temporary use.

Step 4: Secure

-

Fasten flush to the surface. Welding, bolting, or mechanical fastening may be used.

Step 5: Check Gaps

-

Ensure bottom gap ≤¼ inch.

Step 6: Test Strength

-

Apply ~50 pounds force to confirm stability.

Step 7: Inspect Regularly

-

Check for damage, rust, or looseness. Replace as needed.

FAQs

How high are toeboards usually?

-

At least 3½ inches by OSHA rules.

-

4 inches is the most common nominal size in practice.

Can toeboards be shorter?

-

Yes, but only in limited exceptions (e.g., vehicle pits at 2½ inches).

Are they required on balconies?

-

Yes, if there’s a risk of falling objects onto people below.

Do they stop people from falling?

-

No. Toeboards are for objects, not people. Guardrails protect people.

How often should they be inspected?

-

During routine safety checks—typically weekly on active worksites.

Related Safety Elements

Toeboards are one part of a fall protection system:

-

Guardrails (protect people)

-

Midrails (fill gaps)

-

Handrails (assist balance)

-

Safety nets (catch falling people/objects)

-

Debris nets (supplemental falling-object protection)

Practical Tips for Employers

-

Always install ≥3½-inch toeboards where objects could fall.

-

Choose 4 inches for consistency.

-

Train workers on why toeboards matter.

-

Inspect during every safety audit.

-

Document compliance—avoid liability.

Conclusion

The phrase “toeboards are usually ___ inches high and used on landings and balconies” has a clear, fact-based answer:

-

Toeboards are usually at least 3½ inches high, with 4 inches as the widely adopted standard.

These simple barriers save lives and prevent injuries by stopping falling objects. Whether on landings, balconies, scaffolds, or platforms, they are a small but vital part of any safety system.

Installing and maintaining proper toeboards is not just about compliance—it’s about protecting workers, pedestrians, and anyone below.